Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Key Considerations When Choosing Industrial Scales for Your Warehouse Operations

Blog Article

All Concerning Industrial Scales: Key Attributes and Advantages for Your Office

Industrial ranges are essential in enhancing operational efficiency across various markets, supplying attributes such as high ability, precision accuracy, and robust construction. Understanding the diverse types and applications of industrial ranges can provide beneficial understandings right into optimizing your office processes-- yet, the journey does not finish there.

Sorts Of Industrial Scales

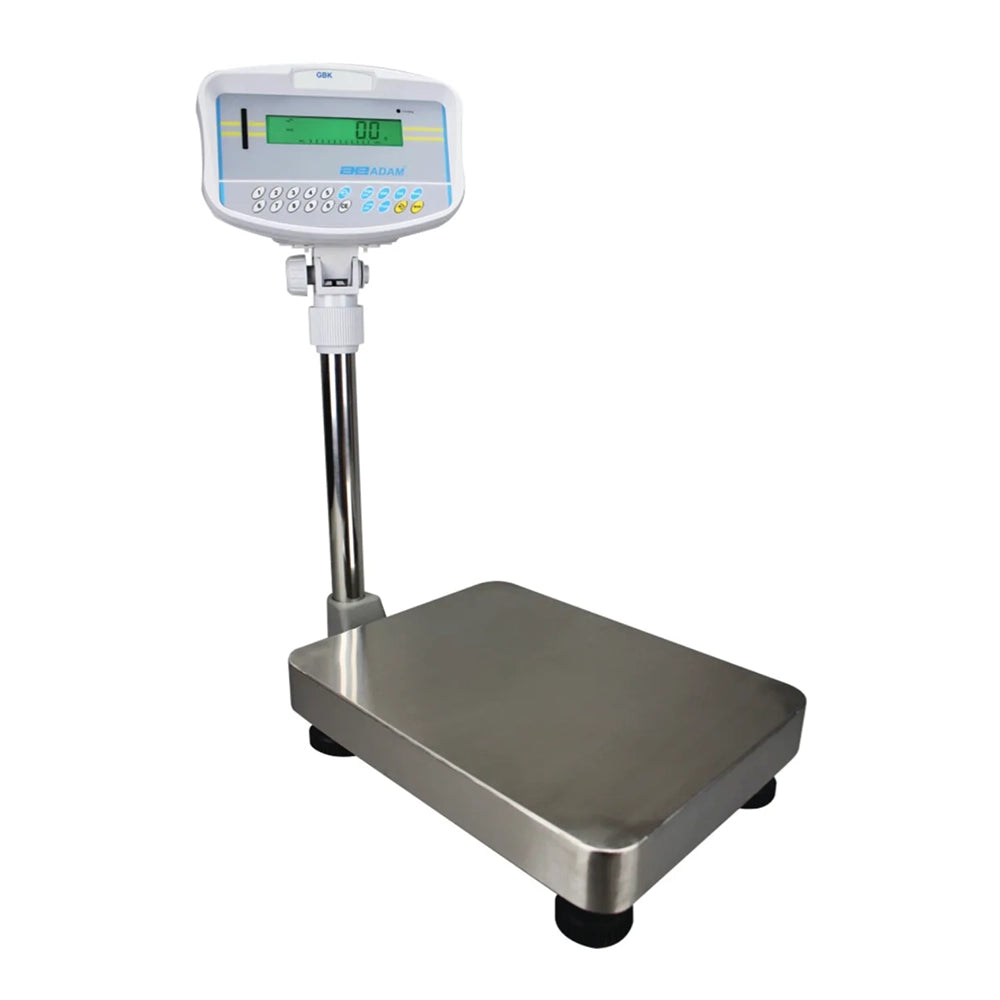

Industrial scales are crucial devices utilized across various markets for precise weight measurement. They are available in several kinds, each designed to satisfy details applications and atmospheres. One typical type is the system range, which supplies a big weighing surface area suitable for cumbersome and heavy items. These ranges are commonly used in warehouses and shipping centers.

An additional widespread kind is the bench range, which is portable and ideal for smaller sized products. These ranges are regularly located in retail and food solution atmospheres, where fast and accurate dimensions are required. Flooring scales serve a similar purpose however are made for durable applications, enabling the considering of large pallets and containers directly on the ground.

Furthermore, digital scales have actually gained popularity as a result of their convenience of use and accuracy. They typically feature innovative electronics that enhance functionality, such as connection alternatives for data monitoring. Additionally, mobile scales use flexibility for on-the-go considering, making them vital in fields like farming and logistics.

Comprehending the various types of industrial ranges is necessary for choosing the right devices to satisfy certain operational needs, ensuring performance and accuracy in weight measurement.

Secret Functions of Industrial Scales

When picking the appropriate kind of industrial scale, it is necessary to think about the crucial features that improve their functionality and viability for details applications. One of the most essential functions is the range's capability. Industrial scales are available in various weight abilities, ensuring that they can accommodate the needs of various sectors, from light materials to heavy loads.

One more crucial function is precision. High-precision tons cells are essential for ensuring that measurements are reliable and consistent, which is essential for supply monitoring and high quality control. Furthermore, the readability of the display screen plays a significant function; clear, digital display screens with flexible illumination permit simple viewing in numerous lighting problems.

Longevity is one more key characteristic, with lots of commercial ranges designed to hold up against extreme environments, including exposure to moisture, chemicals, and hefty use. Some designs even feature stainless-steel or water resistant building. Connection alternatives such as Bluetooth or USB enable seamless information transfer and combination with other systems.

Advantages for Work Environment Efficiency

Furthermore, commercial scales enable faster handling times. With automated evaluating services, employees can swiftly obtain weight data without hand-operated estimations, liberating time for other vital jobs. This acceleration in workflow not just enhances operational efficiency yet additionally aids fulfill manufacturing target dates much more successfully.

Additionally, industrial ranges provide beneficial data that can be evaluated for about his continuous improvement. By checking weight fads, businesses can identify ineffectiveness in their processes and implement restorative activities, ultimately resulting in improved efficiency.

The combination of these ranges likewise supports conformity with industry laws, as precise coverage of weights is commonly called for. This decreases the threat of resource pricey penalties and enhances the business's online reputation for dependability. Industrial Scales. Overall, the consolidation of commercial scales adds to a more effective, economical, and certified workplace setting

Applications in Various Industries

In the food industry, commercial scales are used for section control, recipe formulation, and compliance with health and wellness policies, ensuring food safety and security and uniformity. In a similar way, in the pharmaceutical field, accurate evaluating is important for drug formulation, where even minor disparities can bring about significant governing issues and safety worries.

Building and construction and logistics sectors additionally gain from commercial ranges, as they help in optimizing and taking care of raw materials delivery processes. By providing accurate weight information, these ranges promote far better load planning and compliance with transportation regulations.

Furthermore, the agricultural market Web Site uses industrial scales for considering feed, livestock, and produce, therefore enhancing operational effectiveness and making certain reasonable profession practices.

Maintenance and Calibration Tips

To ensure optimal performance and long life of commercial ranges, regular upkeep and calibration are important. A constant maintenance schedule assists determine prospective problems prior to they intensify, thereby lessening downtime and repair expenses. Operators must regularly clean the scale to avoid debris build-up, which can impact precision (Industrial Scales). Furthermore, examining the lots cells, wiring, and display for wear or damages is essential.

Calibration is similarly essential; it ensures that the range supplies exact readings according to industry criteria. It is advisable to adjust scales frequently-- a minimum of when a year or more frequently if the range is utilized heavily or moved often. Adhere to the manufacturer's standards for calibration treatments, which usually include making use of qualified calibration weights.

In addition, preserving correct environmental problems, such as temperature and humidity control, can enhance scale efficiency and precision. Training staff on appropriate use methods will additionally protect versus misuse that could lead to inaccuracies or damages. By sticking to these upkeep and calibration suggestions, services can guarantee their industrial ranges run effectively, eventually supporting performance and conformity with regulatory standards.

Final Thought

In summary, commercial scales work as important tools for boosting ergonomics across varied sectors (Industrial Scales). Their high ability, precision accuracy, and durable building and construction add to optimum procedures and quality assurance. The assimilation of advanced features, such as electronic screens and information connectivity, further decreases human error and supports governing conformity. By understanding the crucial features and advantages of industrial scales, companies can utilize these tools to boost product use, reduce waste, and ultimately drive productivity.

Industrial scales are pivotal in improving functional performance across different fields, using features such as high ability, precision accuracy, and robust building and construction.When picking the proper kind of industrial range, it is crucial to think about the essential functions that boost their performance and suitability for details applications. By offering exact weight dimensions, commercial scales get rid of the possibility for human error, guaranteeing that materials are evaluated constantly and specifically. It is suggested to adjust ranges frequently-- at least when a year or even more frequently if the scale is made use of greatly or relocated frequently. By understanding the essential features and advantages of commercial ranges, organizations can take advantage of these tools to boost material application, minimize waste, and ultimately drive performance.

Report this page